Immersion Depth for Best Accuracy |

|

|

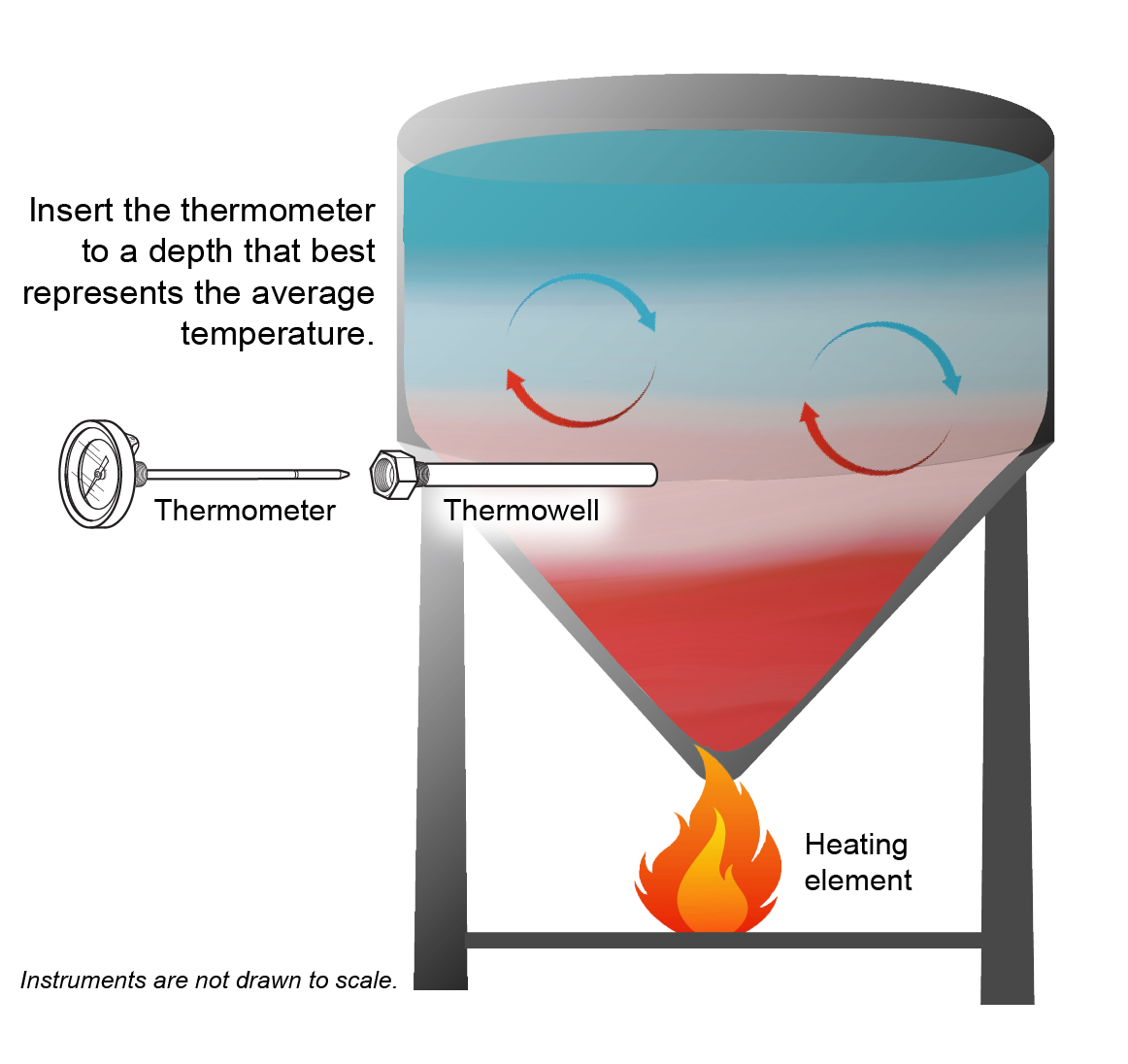

A common question in industrial temperature measurement is, “How far into the medium do I need to immerse the thermometer for an accurate measurement?” It’s an important consideration and depends on a few factors. One factor is of course the size of the vessel into which the thermometer is installed. Small tanks or piping generally offer less available space to insert the stem and options may be limited. In these applications inserting the thermometer close to the center of the vessel generally produces best results. Another factor to consider is the temperature variation of a medium within a confined space. Truly uniform temperature is difficult to achieve, particularly in vessels with a heating element. This can happen as the medium is heated, where the temperature closest to the heating element becomes higher than that at the peripheries. This may be minimized to some degree by mixing, however it’s best to understand the severity of the variance, and insert the thermometer to a depth that best represents the average temperature. Often times there may be a need for a thermowell to accompany the thermometer for protection against high pressure, erosion, and possible corrosion. For best accuracy when using a thermowell, remember that the thermometer stem must fit within that length of the thermowell, with the probe tip close to, or even making slight contact with, the bottom of the thermowell. It’s important to remember, the larger the air gap between the thermowell and the thermometer stem, the longer it takes to respond. A good rule of thumb for inserting thermometers into any medium is that the stem should be inserted one-third to two-thirds deep if possible. |

|

|

|

|

To discuss thermometer care feel free to call our experts at 800-232-5335 or visit www.teltru.com

|

|