When is a Transmitter Needed in an RTD Assembly? |

|

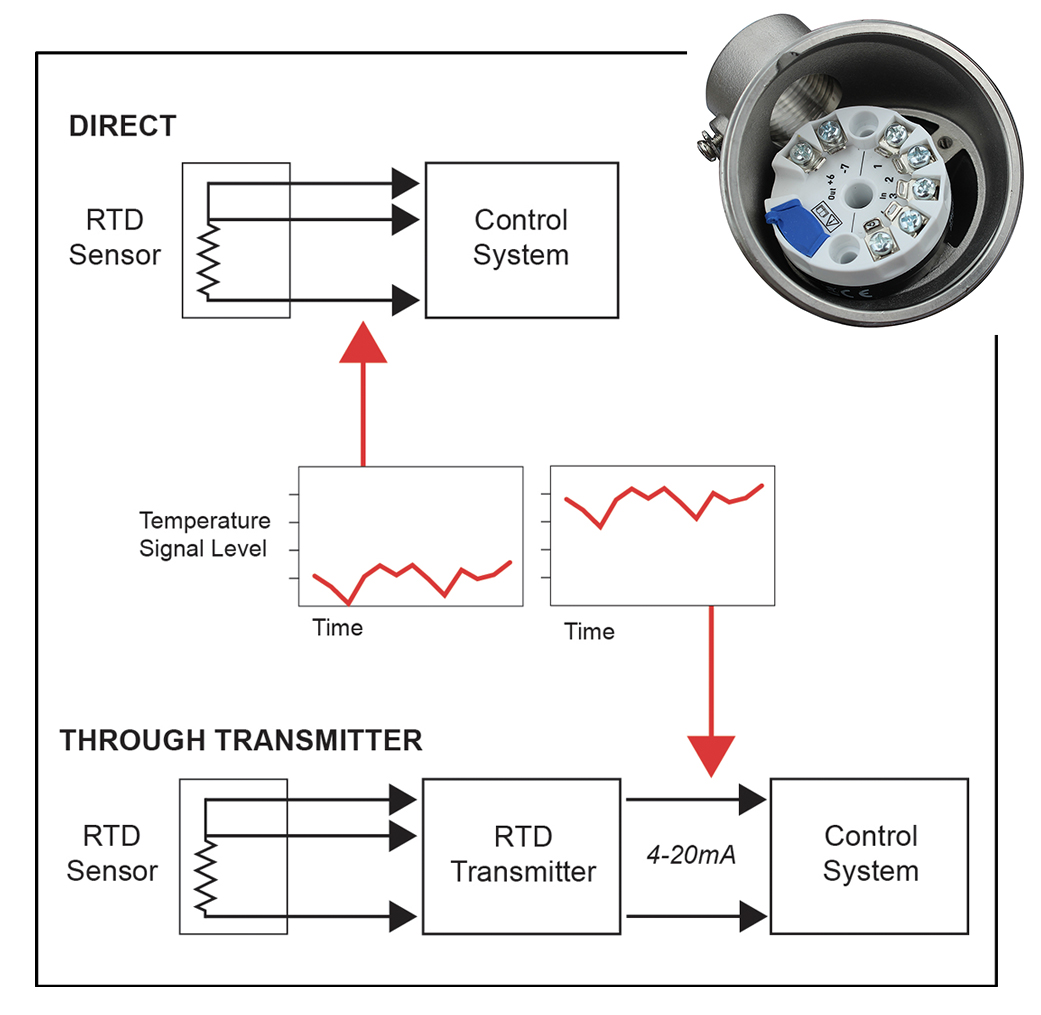

RTD sensors are widely used in industrial applications such as process control, refrigeration systems and environmental monitoring for reliable and accurate temperature measurement. A common question is, when is a transmitter needed in an RTD assembly rather than wiring it directly? Connection options:RTDs can be connected to modern control system in two ways, either directly or through a transmitter. Direct: Low level signal from field mounted RTD sensor is run directly to the control systemTransmitter: A transmitter is installed near the sensor. The purpose of the transmitter is to amplify the signal and allow transmission through a twisted pair cable to the control system. Transmitters change the output to a scaled value, typically 4-20mA which is used by the input to the control system. |

|

|

Direct wiring is generally thought to be simpler and possibly less expensive but it really depends on the complexity of the system. Today’s microprocessor based transmitters offer improved performance for large installations or noise vulnerable systems at relatively low cost. In fact, the cost can be comparable to direct wiring because the cable used between the transmitter and control equipment can be lower cost. The sensor extension wire used when connecting an RTD sensor directly to the control system typically cost 2-3 times that of the shielded twisted pair cable commonly used between a transmitter and control system. Also for retrofits, sensor extension wire can be used for the 4-20mA to the control system connection. Impact of installation environment:Most industrial environments have some level of RFI (radio frequency interference) and EMI (electromagnetic interference) that can impact sensor signal reliability. Wireless communication, high power motors and switching, as well as lighting are common culprits. Amplified signals from a transmitter are much less susceptible to this noise than the low level signal directly from the sensor. In addition, transmitters that are “isolated” reduce the possibility of the signal being degraded by plant wiring that is less than ideal, particularly in older facilities or installations with long runs. Generally speaking, if the system where the RTD is installed has nearby electrical equipment such as motors and power runs or of the run is long, it recommended that you install a transmitter in the RTD assembly to ensure minimal impact by RFI/EMI. For more information, see our RTD Assemblies, or call us at 800-232-5335. |