Protecting Pressure Instruments from Waterhammer |

|

IntroductionWhen you get down to it most pressure measuring instruments are pretty durable and can take a lot of physical abuse both from the media side and the environment. There is, however, a phenomenon that can beat the best of them, either causing unacceptable errors in the measurement or downright irreversible damage requiring replacement of the instrument. That phenomenon is commonly called "waterhammer", but is in reality rapid spikes in pressure that occur in the fluid media sensed by a pressure gauge or transmitter.Waterhammer is a complex phenomenon that can be very troublesome and is generally misunderstood. Failure to protect sensitive instruments can be very costly. What is Waterhammer?In most cases the condition occurs when the media is an incompressible fluid, generally liquids but sometimes gases. A good example is in your home water system. Sometimes when you suddenly stop the flow of water in a shower, you hear a banging sound in the walls. That is waterhammer.In the industrial world, the offending devices are all types of valves, including solenoid and relief types; and various types of pumps, because they suddenly affect the flow of the fluid. Again, it is this sudden stop of the flow that creates the pressure spike. In general you find the potential for waterhammer evident in most liquid systems. The medium could be oil, water or other incompressible fluid. While a system designer will try to minimize the potential for this problem, in reality it is often an impossibility to eliminate the conditions that cause pressure spikes. Applications where waterhammer is a risk include

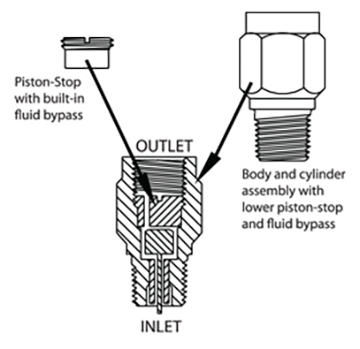

Effect on Pressure Gauges and TransmittersThe biggest misconception about waterhammer is that the pressure spikes can't be any greater than the maximum system pressure. It is entirely possible and likely that in a hydraulic system where the maximum pressure is designed to be 500psi, the pressure spikes generated can be up to 8 times that pressure, which will cause a failure of the pressure measuring instrument. It has been documented in tests using a very fast responding quartz pressure sensor and digital storage oscilloscope that this is the case. Failure to properly protect gauges and transmitters will likely result in damaged instruments, which are often beyond repair.What happens to the instrument that renders it a throwaway? All gauges and transmitters have an elastic sensing part, frequently a diaphragm in a typical electronic pressure transmitter, or a bourdon tube in a gauge. This sensing mechanism is designed to work in an elastic way over the pressure range of the device, with an overpressure capability of generally from 1.3 times the range with a gauge to 2 times the range with most transmitters. For example, if the calibrated pressure range of a transmitter were 0-200psig then the overpressure capability would be up to 400psi. This means that any spikes or overpressure not exceeding the 400psig would not affect the accuracy or performance in any way. If the pressure goes higher than the overpressure limit, the sensing mechanism becomes plastically deformed and will not return to its proper operating state. That usually results in a zero shift at best, and a useless instrument at worst. How to Protect Pressure InstrumentsAn orifice restrictor in the process connection of the pressure measuring instrument, or a threaded-on attachable snubber, is a simple and effective means of preventing pressure spikes from reaching the sensitive mechanism and causing irreparable damage. There are various designs―from a simple restrictor which has a very small hole, to an encapsulated precision O.D. piston that slides within a bore with very tight I.D. dimension―all which slow down the progression of the waterhammer shock wave. A needle valve is also a tool that can be used to reduce the effect of the shock wave on the instrument. |

|

|

It is important to point out that snubbers only protect the instrument against pressure spikes, that is, overpressure for very short time periods on the order of milliseconds. If there is a sustained overpressure in the system, then the protection is lost and the pressure instrument may suffer irreparable damage requiring replacement once the cause of the overpressure is identified and eliminated. Snubbers are available for sale with all Tel-Tru pressure gauges and transmitters, and should be specified on all incompressible fluid applications. |

|

|

If you have any questions or need recommendations about protecting your pressure instruments, feel free to contact us. |

|