Immersion Methods of RTD ProbesAn immersion sensor is one of the most reliable and accurate ways to measure temperature. There are two primary ways to install immersion sensors into the system; direct and indirect. |

|

|

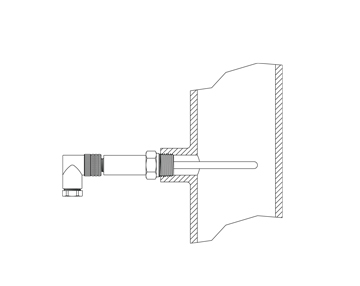

Direct method

The direct method involves installing the RTD assembly directly into the system (Figure 1), through the wall of a pipe or vessel for example. This can be accomplished through a number of process fittings which are specific to the application. The main advantages of the direct method are:

|

Fig. 1: Direct installation |

|

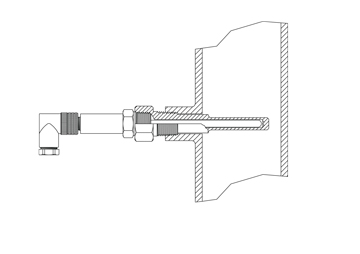

Indirect method The Indirect method incorporates a separate thermowell (Figure 2). With the thermowell properly installed, there is no contact between the fluid or gas and the RTD sensor assembly itself. The main advantages of the indirect method are:

The disadvantage is generally a slower response time. |

Fig. 2: Indirect installation |

|

For additional product specifications, contact us. |

|