Choosing the Best Transmitter Configuration |

|

|

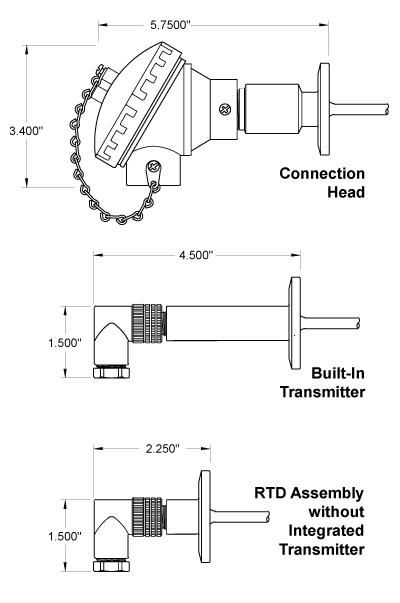

When choosing the best RTD transmitter configuration for your system, one of the main considerations is how to integrate the transmitter, which is a circuit that converts the low level RTD signal to a high level, such as 4-20mA or HART, for transmission to a control system. Depending on the configuration, the transmitter can be replaceable, built into the housing or located a short distance from the RTD sensor itself. These three common arrangements are illustrated below. |

|

|

|

|

For help configuring an RTD for your application contact us. |

|