Extending the Life of your Industrial ThermometerQuality thermometers are built to provide a long service life. Here are a few tips to help you get the most out of your instruments. Environmental conditions: Most quality industrial thermometers are hermetically sealed and are suited for use in environments where humidity or moisture is high. If your thermometer is submerged or subjected to high pressure spray and not rated for those conditions, water damage will likely result. |

|

|

Vibration: |

Vibration can cause accuracy problems and premature failure. Vibration can cause accuracy problems and premature failure. |

|

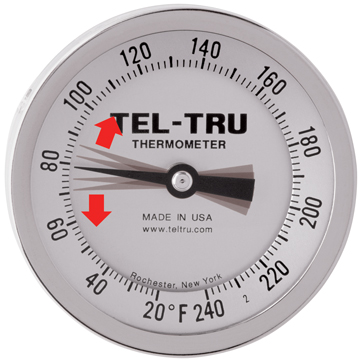

Out of range: |

|

|

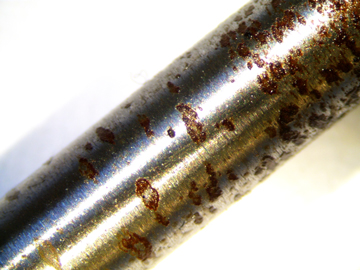

Process fluid: Impact: |

Corrosive fluids can cause premature stem failure. Corrosive fluids can cause premature stem failure. |

|

For additional product specifications, contact us. |

|